Tube Forming Technology +

Automation Solutions

Tube Forming Technology + Automation Solutions

Reduce manufacturing costs by identifying the right technology to solve your problem. Wauseon TubeTech, from Integrion Automation is ideally equipped to help firms needing to 3” and below tube fabrication.

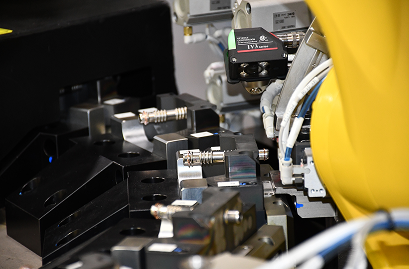

Integrate robotic automation into your tube forming operation to decrease waste and improve speed and accuracy.

Automating the Process of Creating Tubes: Watch our animation for a glimpse into how Wasuseon TubeTech can reduce costs by boosting speed, accuracy, and efficiency through automation.

Tooling Development Solutions

Tooling Development Solutions: Our dedicated tooling development team has been working closely with our customers for over 40 years to achieve solutions that improve business results.

Completed Design Package Includes:

- Tooling component prints

- Set-up information

- Coating recommendations

- Lubricant recommendations

Key Benefits:

- In-house CNC machining facility

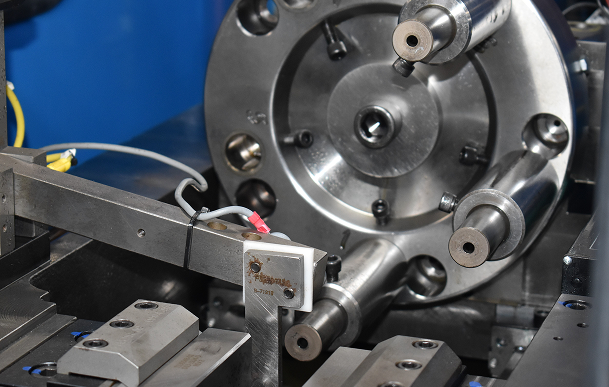

- Dedicated end forming machines for tooling tryout with equivalent models for every machine

- 572 years combined in-house tooling experience

Get connected with a Wauseon TubeTech specialist to discuss your project.

Additional Tooling Development Services

We offer short-run tube end forming and end finishing using our own dedicated development machines. This service is ideal when it is more economical for our customers to employ our services in the initial stages of developing a tube end form fabrication for their own production process.

Additionally, we offer:

- Part Progression Drawings

- Finite Element Analysis (FEA)

- Capabilitiy Studies

- Carbinite Surface Texturing

Specialized tube forming technologies and machines for end forming and end finishing.

END FORMING MACHINES

We have three series of machines that feature a ram force of up to 80 tons. They can accommodate ferrous / non-ferrous metal and plastic tube diameters up to 3” (76.2mm).

Our machines are ideal for forming beads (front, back, double, single, Jiffy-Tite, SAE J1231, SAE J1453 O-Ring Face Seal (ORFS)), swages / reductions, expansions, flares (SAE J533), and combination endforms such as SAE J2044 Quick Connects, among several other endforms.

- 1000 Series: Our 1” Ø tube end former is ideal for engine oil cooler (EOC), transmission oil cooler (TOC), brake, and fuel.

- 1300 Series: Our 1.5” Ø tube end former is ideal for seat products, fuel filler tubes, and automotive A/C lines.

- 1300 Series: Our 1.5” Ø tube end former is ideal for seat products, fuel filler tubes, and automotive A/C lines.

END FINISHING MACHINES

- 2100 Series: Hydraulic and electric rotary roll / cut end finisher models for up to 0.75” (19.05mm) diameter tube.

- 2600 Series: Our 2600 series hydraulic rotary roll / cut end finisher model is for up to 2” (50.8mm) diameter tubes.

- 21CS-EL DECOAT MACHINE: Mechanically remove coating prior to an endform process, such as a flare or quick connect.

CE COMPLIANT END FORMERS

Our tube fabricating equipment conforms with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). This allows us to sell our end formers freely in any part of the European Economic Area, including the European Union, the European Free Trade Association, Turkey, and the United Kingdom.

CUSTOM END FORMING SOLUTIONS

With labor shortages across the manufacturing industry, companies turn to Wauseon TubeTech for custom tube forming and automation solutions. We help you figure out how to improve and/or automate your tube forming processes.

Have equipment from other companies? No problem. Whether it’s our machines or another firm’s, we can integrate and automate to meet your specific needs.